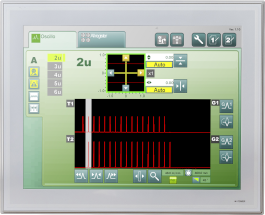

Touch Panel Automatic Register Controller

SK-2090

■Features

- Standard equipped both length and Side-lay registration output.

- LED type scanning head achieve longer life and the angle changeable bracket perform reliable sensing especially for aluminum or paper printing job.

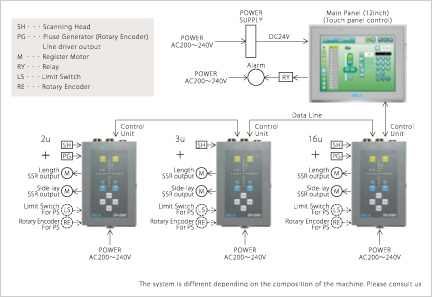

- Control Unit have independent controller and simple communication system contribute both less wirings and stable control against noise.

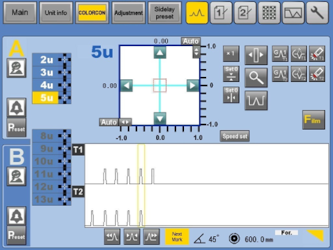

- User friendly operation by touch panel with USB port for mouse operation.

■Specifications and Performance

| Correction method | Length: Compensator roll correction method Side-lay: Cylinder correction method |

|---|---|

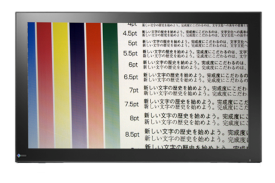

| Detection accuracy | Length: ±0.01mm Side-lay: ±0.02mm |

| Printing speed | 10 to 500m/min Max. (Cylinder size: 600mm) |

| Fine adjustment range | ±9.99mm in each direction |

| Register Alarm range | 0.1 to 9.9mm variable |

| Power supply | AC200V to 240V ±10% 1φ50/60Hz 0.5kW |

| Environment Condition | Temp. 0 to 40°C Humid. 20 to 80% (Without dew condensation) |

■Configuration

| Main panel | 1unit |

|---|---|

| Control unit | number of channels ( printing units -1) (Max.15ch) |

| Scanning head | (number of control unit) pieces |

| Pulse generator | 1 piece |

| Option | Length direction preset device Split system |

■Precaution

| installation condition | Pulse generator should be synchronized with printing cylinder rotation. Scanning head are installed before the dryers of the printing units on 25mm square rod. In case of printing on transparent films, reflecting plate is required. |

|---|---|

| Wiring Between Units | The power line and the signal line separate completely. The signal line should be the shielded cable. |

| Length correction speed | 1mm/sec on the web. |

| Side-lay correction speed | 0.5 mm/sec for printing cylinder movement. |

| Register Motor | We recommend the use of single phase synchronous motors. Power supply for register motors must be required for both direct drive and over current circuit. |