Sectional drive control

COLOCON LC+®

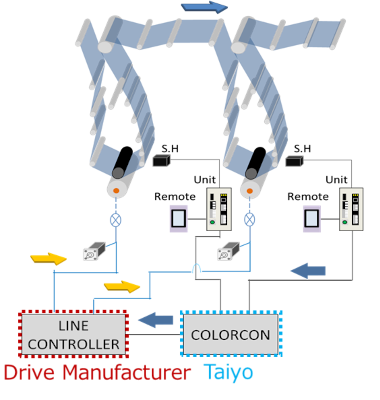

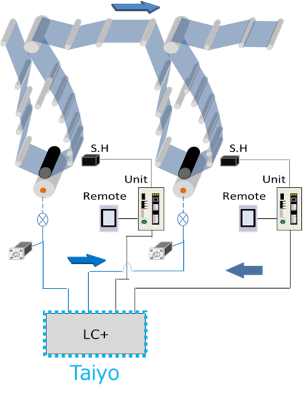

COLORCON LC+🄬 is a drive control system for gravure printing machines developed by our company.

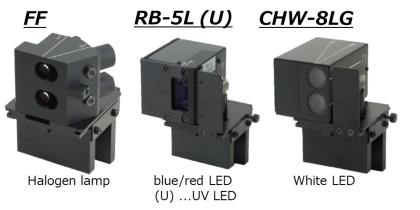

■Compatible with various motors

- In order to flexibly respond to user requests,

both servo motors and inverter motors can be selected.Compatibility Yasukawa servo motor ✓ Vector motors from various companies ✓

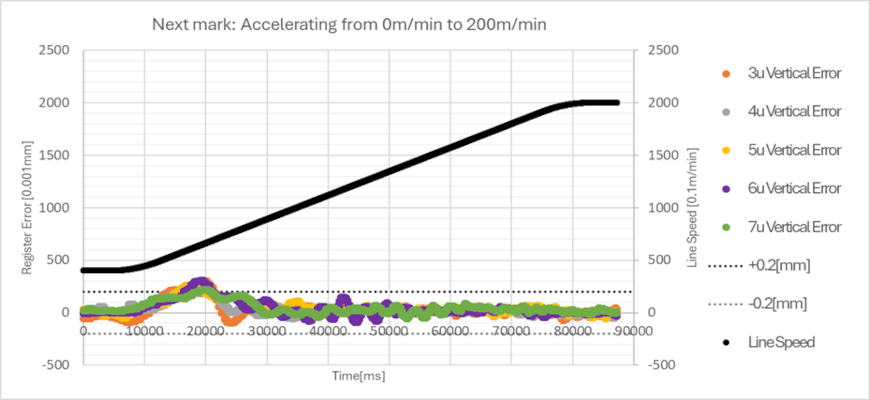

■Stable orientation control

-

By COLORCON LC+🄬's new orientation control algorithm,

upstream unit does not affect downstream unit,

losses can be minimized, especially during acceleration.

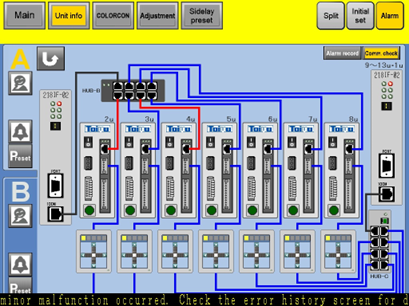

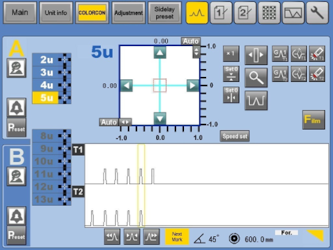

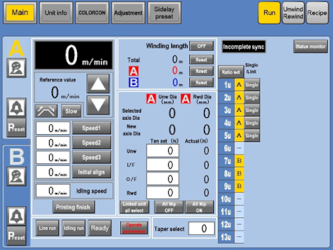

■Easy operation

-

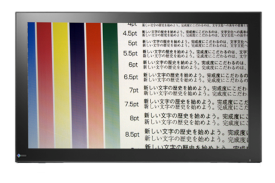

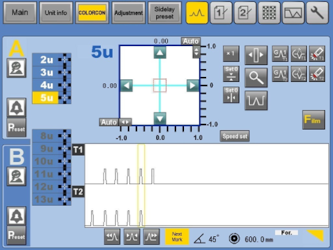

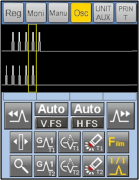

The LCD touch monitor allows operation on both the COLORCON side and the drive side.

Operators who already use Taiyo products can make the transition smoothly.

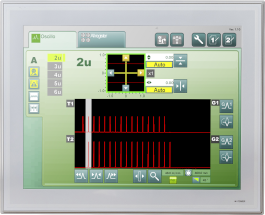

-

The LCD remote monitor also allows operation of both the COLORCON side and the drive side from each unit.

Also, the waveform display function is expected to improve productivity.

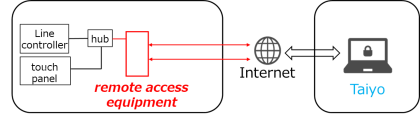

■Remote and One-Stop

Troubleshooting

- COLORCON LC+🄬 communication error detection function makes initial problem solving easier.

- By introducing remote access equipment, problem solving can be carried out over the Internet.

- If any problems with COLORCON or the drive occur, all enquiries will be handled by Taiyo Electric Industry Co., Ltd.