Inspection System

OFT™️ Series

The inspection system OFT™ series inspects printing patterns while high-speed printing.

This system images the surface of the printed film by line color camera, and it stores as reference image and actual image, and detects a defect by a pattern matching method.

■Features

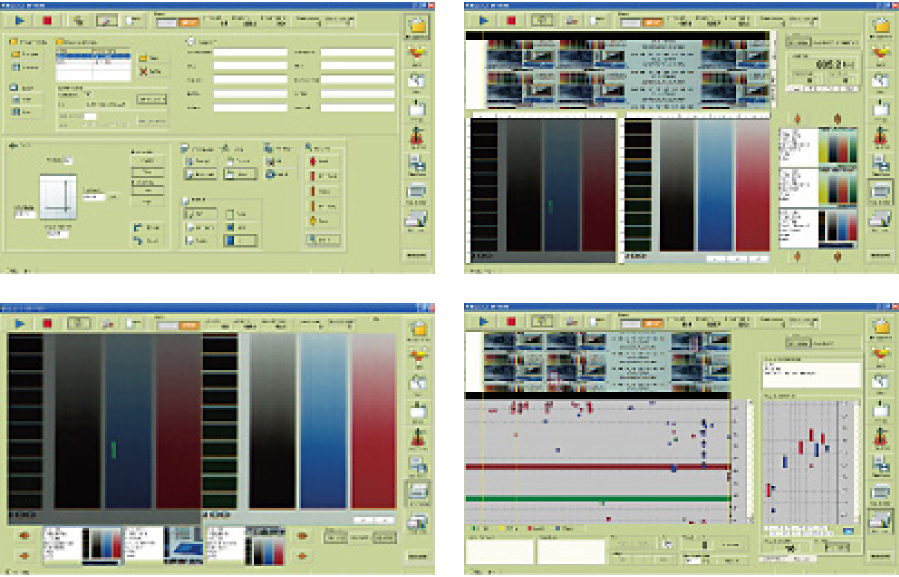

- Easy operation

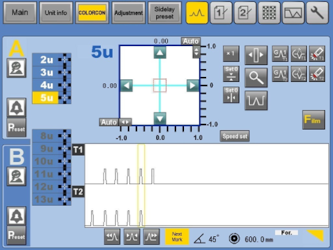

Various operations and a condition setup were visually carried out to the screen composition which can be set up simply intelligibly.

It can be operated simply by this and leads also to time shortening to inspection. - Development of specified partsThe inspection stable by development of an exclusive camera and an exclusive inspection circuit was realized.

- System protectionThe system damage by a sudden down of the power supply of the power failure etc. is prevented by recording the data of the system in the storage device with reliability.

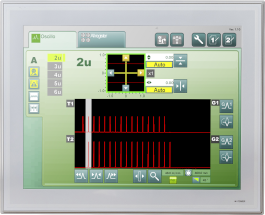

- Colorcon made of our company synchronization functionThe registration error history of each CH(unit) is displayed.

※Maximum channel : 12 (vertical and horizontal total)

The registration error history and defect history can be managed collectively, it is possible to take over it to the next process smoothly.

■Specifications

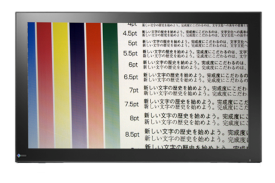

| Camera | Pixels: 4096 [Pixels] Drive Clock: 40 [MHz] Max.No.of Camera: 2 [sets] |

|---|---|

| Light source | Three wavelength Fluorescent Lamp (High Frequency Light) |

| Inspection PCB | Color Data: Total 24 [bit] Inspection Circuit: Three Circuit (Pattern Matching Method) |

| Display/Store Device | OS: Windows®XP Display: 22inch wide LCD screen Store Data: Removable-Storage Printer: Color Ink Jet Printer |

| Counting Device | Encoder: 5000 [Pulse] |

| Others | Printing Speed: 350 [m/min] ※600[mm] or more of cylinder size. Temperature/Humidity: +10 to 35°C/Less than 90% RH, without dew Power Source: AC200 to 240 [V] ±10% 50/60 [Hz] 1KVA |

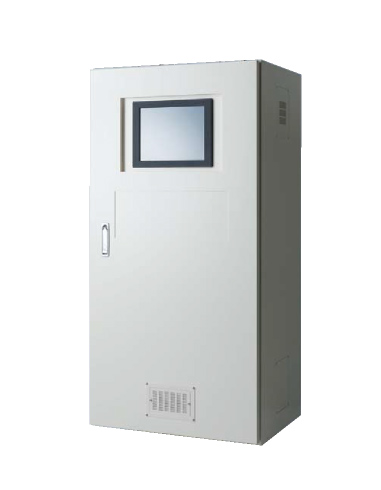

■Configuration

Standard configuration

- Inspection System Main Body

W650×D685×H1,720 - Camera Box

- Power Source Box

- Reflective Light Unit

- Back Light Unit

- Touch Roll Encoder

- Labeler (Optional)

■Screen