Web High-Vision Printed Pattern Monitoring Equipment Model

HV-300

It takes considerable skill to visually check the color tone and orientation of high-speed printed materials, which are quality check items.

The Web Hi-Vision HV-300 model combines a high-density digital color camera with an LED light source, etc., and displays high-speed moving printed matter as clear color still images on a monitor, allowing everyone from beginners to experts to see the patterns, colors, and orientation, etc., can be easily monitored.

■Features

-

Up to 12x zoom possible

6x motorized zoom lens

2x digital zoom

(The halftone dots on the print can be seen.) - The miniaturization of the camera box allows installation even in narrow spaces that were difficult to install with previous models.

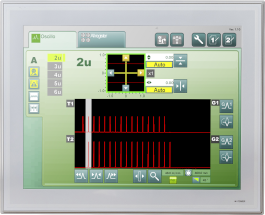

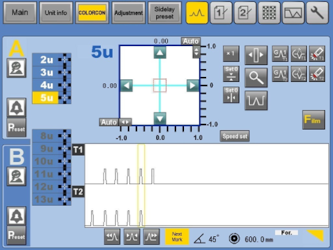

- Switching the picture stationary timing (machine synchronization or manual internal synchronization) can be easily set using the touch panel.

- By adopting an LED strobe, uneven lighting is reduced compared to previous models.

- The traverser mechanism allows movement to a specified position. (manual/automatic operation function)

- The device can be operated using a touch panel monitor.

-

Digital zoom (up to 2x) is possible by pinch in/out.

-

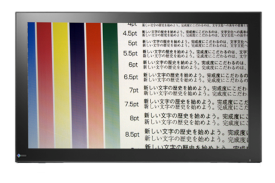

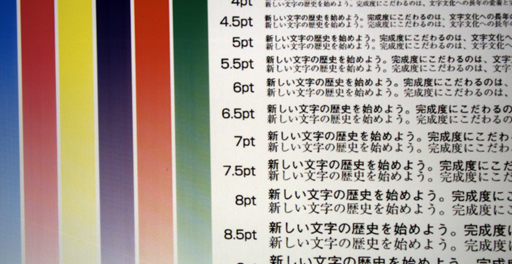

By adopting a high-resolution camera, images are clearer than those of previous models.

Conventional model images

HV-300 images

■Specifications and Performance

| Applicable printing machine | Gravure rotary press |

|---|---|

| Camera | High performance CMOS 2 million pixels |

| Monitor | 21.5 inch wide (touch panel monitor) |

| Adaptive printing speed |

MAX.400[m/min] (cylinder circumference 600mm/750rpm) ※From 350 rpm, image updates are changed to once every two cylinder revolutions. |

| Monitoring range |

Vertical: 0~360° (encoder input) Horizontal: Machine width (with traverser installed) Maximum viewing angle Approx. 116×65[mm] Minimum viewing angle Approx. 8.6×5[mm] |

| Traverser Movement Speed | Configuration reference |

| Power supply | AC100[V]±10[%]1φ50/60[Hz]15[A] |

| Applicable environment |

Temperature:0~+40[℃] Humidity: 90% or less, no condensation Atmospheric gas: None Dust: None |

■Configuration

| Print pattern monitoring device main unit | 1 unit |

|---|---|

| Camera box | 1 unit |

| 21.5 inch wide (touch panel monitor) | 1 unit |

| Pulse generator (can be shared when installing COLORCON) | 1 unit |

|

Traverser equipment <moving speed> Manual low speed Initial setting 10[mm/s] Manual high speed Initial setting 200[mm/s] Automatic round trip operation Initial setting 60[mm/s] ※Movement speed can be changed arbitrarily Other autonomous driving 1,000[mm/s] |

1 unit |

| Detection surface panel | 1 unit |

■Functional description

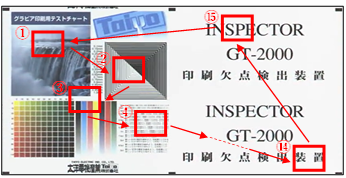

-

Up to 15 arbitrary shooting points can be registered.

Thumbnails of the images taken are displayed at the registered shooting points.

-

During memory auto operation, the camera moves to the shooting points

in the specified order and repeats shooting.

[ shooting order:①→②→...→⑭→⑮→①→②→... ]