Mark Vision Trim Monitoring Device Model

MRV-021

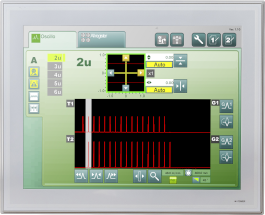

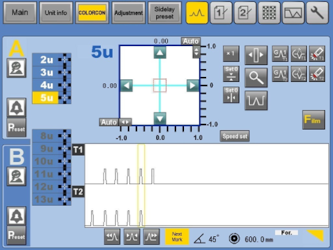

To display trim marks quickly and accurately, MarkVision is intuitively operated via a touch panel.

■Features

- Mark Vision makes it easy for anyone to check the orientation, which tends to rely on experienced people.

- All units can be synchronized in one place. *line shaft printing machine

- Mark Vision allows you to quickly fine-tune your orientation over time from the image.

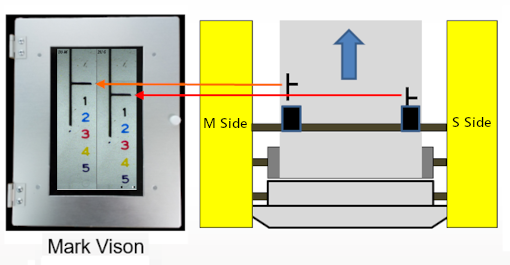

- Adjusting and checking twists is also possible quickly by adopting two camera units.

Simple operability

Contribute when printing starts

■Specifications

| Power supply voltage | AC100V ±10% 5A or AC200~240V ±10% 3A | |

|---|---|---|

| Main unit | Monitor | 7 inches *Optional 10 inches ・ 15 inches |

| Operation specifications | Touch panel screen operation (up and down operation, brightness adjustment, etc) |

|

| Moving specifications (up and down movement) |

small button: ±1P, large button: ±10P | |

| Vertical resolution (up and down movement) |

Small button 1P Printing circumference [mm] / 1000, 1024, 2000, 2048(by pulse number) |

|

| Encoder input method | Line driver Voltage input (5V) 1000P, 1024P, 2000P, 2048P |

|

| Camera unit | Number of pixels | 2 megapixels |

| Lens | Fixed magnification lens | |

| Zoom function | Digital zoom Vertical: about 2 x Horizontal: about 2 x |

|

| Paper viewing angle (vertical× horizontal) |

Maximum viewing angle 26×14 [mm] Minimum viewing angle 13×7.5 [mm] |

|

| Distance between papers (vertical× horizontal) |

10[mm]±2 | |

| Light source | LED 1 row 9 pieces ×2 rows (Total 18 pieces) | |

| Brightness adjustment | Adjustable via touch panel | |

| Focus adjustment | Adjustable via touch panel or camera adjustment mechanism | |

| Adaptive printing speed(Web speed) | Rotational speed: Maximum 800 [RPM] | |

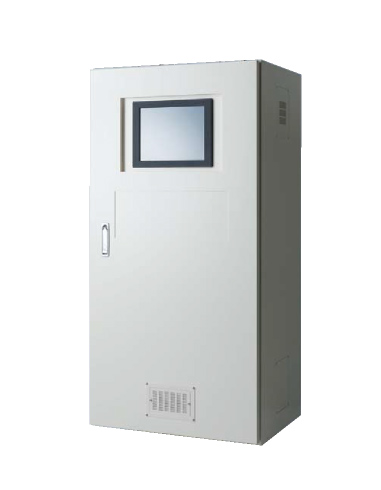

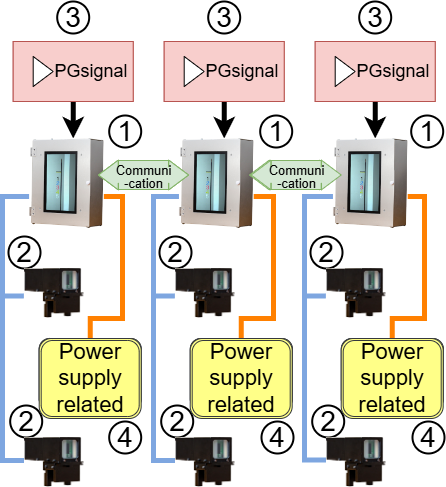

■Equipment configuration

*Multiple units can be installed- ① monitor box (main unit)

- ② camera unit (BOX)

-

③ PG signal (mechanical synchronization signal)

Obtained from COLORCON or printing press. -

④ power related

Breaker

Noise filter

Switching power supply - ※ A milky white detection panel is required separately on the back of the equipment.

■Function description

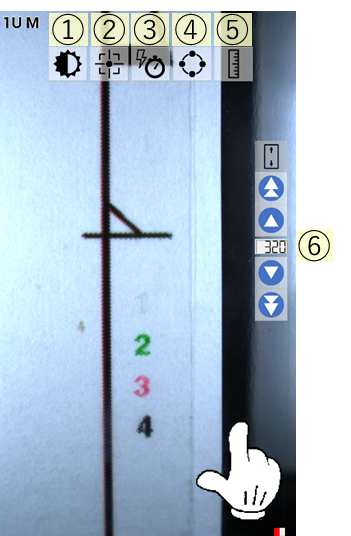

Touch panel operation

- ① Brightness adjustment

Adjust brightness manually - ② Autofocus function

By selecting the image you want to see, you can automatically focus - ③ Manual sync selection

Manually select the location where you want to view the printed matter - ④ Unit synchronization

When multiple units are installed, other synchronizations are also linked.

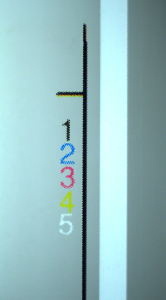

※ *Only when installed on a line shaft printing machine - ⑤ Ruler grid line display

Display a ruler or grid-like line on the image and visually check the size - ⑥ Image up/down function

Image up/down operation

Check the alignment of the twist

- If you purchase two camera units, you can check the alignment of the twist.

Trim mark image